ADA Keypads

Project Description

Why does your product need an ADA keypad?

Typically, any machine that consumers will interact with must meet ADA standards. Meaning that if the main user interface is not fully accessible by someone in a wheel chair the machine must have a different way for that person to control it.

What is an ADA keypad?

ADA (Americans with Disabilities Act) requirements can be a bit tricky to understand and translate. The goal of adding an ADA keypad to your design is to allow people to fully operate a machine while they are in a wheelchair.

What are ADA keypad height requirements?

Forward Reach Limits

Unobstructed Forward Reach

According to ADA.gov, Where a forward reach is unobstructed, the highest forward reach shall be 48 inches (1220 mm) max, the lowest forward reach shall be 15 inches (380 mm) minimum above the finish floor or ground.

Obstructed Forward Reach

If there is an obstruction 20 inches of depth, the highest forward reach shall be 48 inches (1220 mm).

If the reach depth exceeds 20 inches (510 mm) it can have a maximum depth of 25 inches (635 mm) and the highest forward reach shall be 44 inches (1120 mm) maximum.

Side Reach Limits

Unobstructed Side Reach

If there is clear floor or ground space that allows a parallel approach to the machine and the side reach is unobstructed, the highest side reach should be 48 inches (1220 mm) maximum and the lowest side reach should be 15 inches (380 mm) minimum above the finish floor or ground.

Obstructed Side Reach

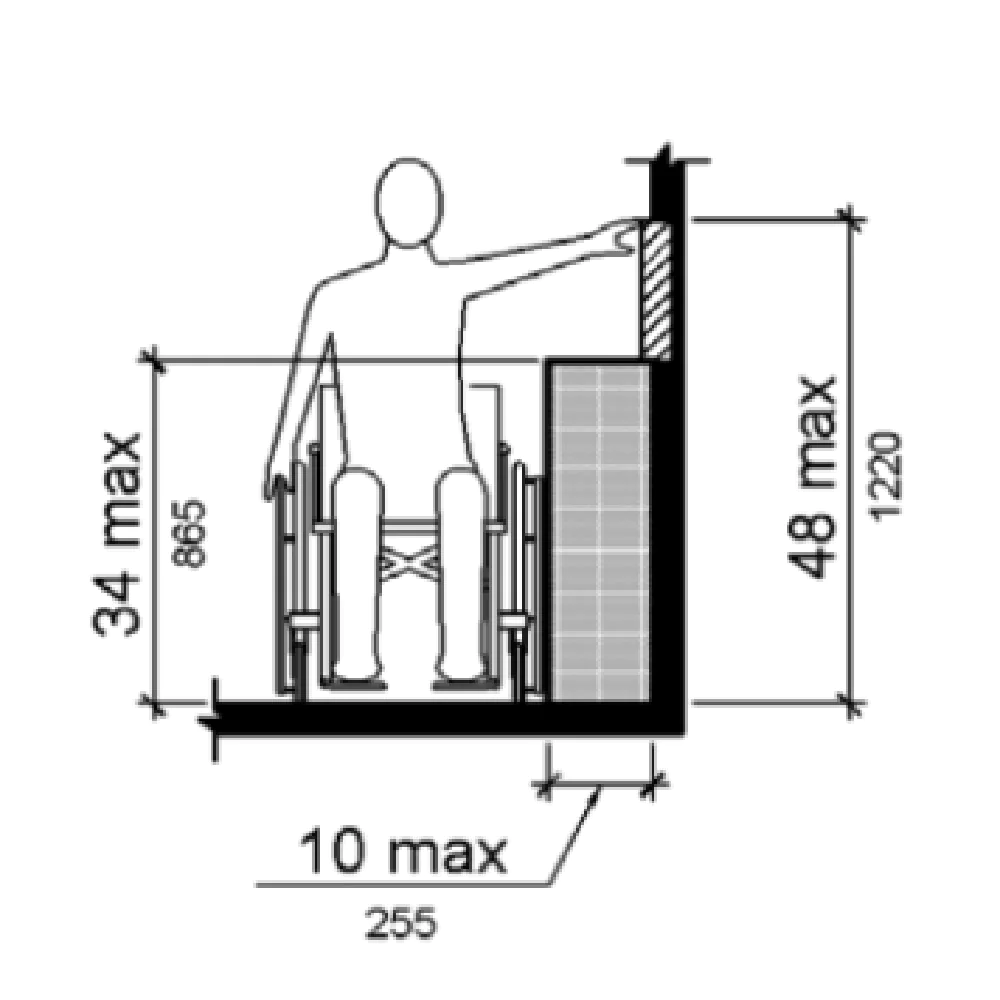

The maximum height of the obstruction for side reach access of the machine should be 34 inches (865 mm) and the depth 24 inches (610 mm).

If the obstruction has a maximum depth of 10 inches (255 mm), the highest side reach should be 48 inches (1220 mm) maximum.

If depth of the obstruction exceeds 10 inches (255 mm) (24 inches maximum), the highest side reach should be 46 inches (1170 mm).

What is this keypad? How does it communicate?

When designing an ADA Keypad, the goal is to simplify user interaction with your product. This design has three buttons. A left arrow, a right arrow and a select button. With just three buttons the complete User Interface can be accessed. This is a capacitive touch keypad, capacitive touch technology has no moving parts. A special injection molded plastic lens sits above the keypad which allows for easy cleaning. The capacitive touch keypad follows USB HID protocol meaning that there are no additional drivers needed, as soon as the keypad is plugged into a USB port it is automatically recognized by Linux or Windows.

Our designs are manufactured in-house using our high-end automated pick-and-place line. We are a UL and Intertek approved manufacturing facility. After running through our SMT line the keypad is conformally coated by our automated conformal coating machine making it “water resistant.”

Let us design your ADA Keypad

Blue Sparq designs and manufactures custom Capacitive Touch or Membrane switch ADA keypad solutions for products in various industries. Our capacitive touch technology has been developed over 11 years and customers like Coca-Cola, Pepsi and McDonalds depend on our capacitive touch keypads for their drink dispensing equipment. We implement custom algorithms that we have developed over the years to deal with things like water, cleaning, false press detection, auto calibration. Our capacitive touch keypads also have a bootloader for remote updating of firmware.

Capacitive touch Keypad development is just one of our many capabilities, please check out our capabilities page and see what else we can do for you!