There are two capacitive touch design methods we use, PCB and Film Method. Depending on the requirements we provide our customer with the best approach.

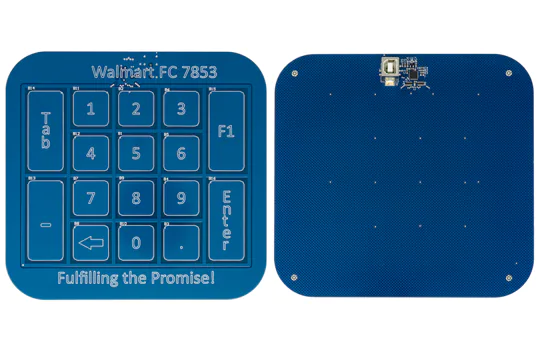

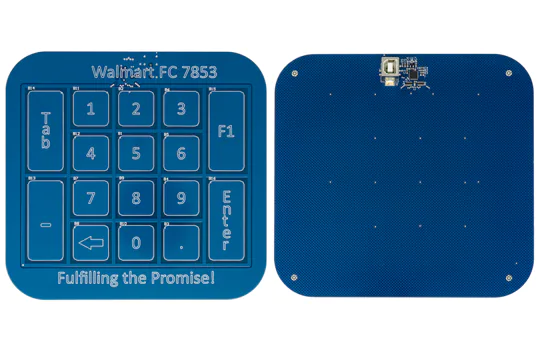

PCB Method

The PCB Method consists of the capacitive touch buttons being a part of the circuit board. Typically, the PCB Method keypad gets mounted to the final product or a graphics layer (overlay) is applied directly onto the circuit board.

Film Method

Film Method is typically used when a PCB Method keypad cannot easily be mounted. A film keypad has a conductive ink layer under the graphic overlay which terminates to a ribbon. The ribbon is then connected to our electronics. This is how we are able to implement capacitive touch technology in areas where space is limited.

Touch, proximity and gesture recognition are all customizable in our designs.

Touch

A touch is detected by monitoring a change in capacitance of a given surface. When the microcontroller detects any change in base capacitance of a capacitive touch sensor it triggers an output.

Proximity

Proximity detection is done with a sensor that is capable of detecting the presence of a finger or hand without making contact.

Gesture Recognition

Gesture recognition is done with several proximity sensors. The software can interpret the triggering order of these sensors to decipher a gesture.

Haptic Feedback

There are two types of technologies used to give our keypads haptic feedback, LRA (linear resonant actuator) and ERM (eccentric rotating mass).

LRA Haptics

LRA haptics have no external moving parts and depend on resonance to create vibration.

ERM Haptics

ERM haptics rotate an unbalanced mass which creates the displacement we perceive as vibration.

Audio Feedback

It is very important that a user knows that he has successfully interacted with the machine. Audio Feedback is one way to communicate this information to the user. Audio feedback is often achieved by using a piezo buzzer or speaker.

We can connect the capacitive touch keypad to your product’s electronics via the following: USB, UART, RS232 - RS485, I2C - SPI, or Ethernet.

USB

The buttons of our USB capacitive touch keypads can be mapped to any key on a computer keyboard, mouse or joystick. Since our USB keypads use the HID interface, Windows and Linux do not require a special software driver.

An example below is a custom capacitive touch mouse trackpad and buttons mapped to keys on a computer keyboard with a dead front, lighted glass overlay.

UART

We prefer using the UART (TTL TX, RX, GND) when connecting directly to the product's main controller. This is suitable only when the cable connection length is short.

RS232 - RS485

RS232 or RS485 is a great choice when the cable connection length is long.

I2C - SPI

I2C or SPI is chosen when UART communication is unavailable.

Ethernet

On special occasions we have connected our keypads directly to Ethernet or CAN Bus.

Fore Light

Selective Lighting with Translucent White Icons

Selective lighting is simply the ability to control the illumination of individual button icons. With translucent white button icons you will be able to still see them even when the back lighting is off.

This method is used when the illumination of a button is meant to show the status of that button. We can use different colors of light produced by RGB LEDs to indicate multiple modes of operation. An example of this is the call button in an airplane, when the button is pressed it illuminates.

Selective Lighting with Dead Front Technique

Selective lighting is simply the ability to control the illumination of individual button icons. The Dead Fronting technique is the ability to control the visibility of button icons or logos.

We have perfected the Selective Lighting and Dead Front Techniques using Glass and Plastic overlays. Now you can illuminate button icons separately and when that illumination is turned off, the icon disappears into the background.

Not only does this add a futuristic look and feel to your product, it also can be used to simplify the operation of your product. By illuminating function specific buttons you can make your control panel easy to operate.

Indicator Lighting

Indicator LEDs are a simple way to communicate button status. Bi-Color or RGB LEDs can be used to provide even more information to the user. Indicator LEDs can be used with either PCB or Film type capacitive touch systems.

A great example of this in automobiles, is the cruise control or defrost buttons. Usually these buttons are illuminated with an additional indicator light. When the cruise control or defrost are active the indicator light will be turned on.

A Fast Touch™ capacitive touch system consists of Fast Touch™ electronics, conductive circuit layer and graphic overlay. Fast Touch™ electronics is the name given to all the electronics and firmware used by BLUE SPARQ to produce successful rapid prototype capacitive touch systems. At the heart of the Fast Touch™ electronics is the Fast Touch™ IC. The various touch pads of the conductive circuit layer are connected to the Fast Touch IC. The pads formed by the conductive circuit layer could be copper pours on a PCB or printed conductive elements on a film. The overlay is non-conductive and placed on top of the circuit layer. The overlay material could be glass, lexan, acrylic or any other plastic of various thickness. When the human hand is brought in close proximity to the pads of the circuit layer, the capacitance associated with the pad changes. This causes a change in the voltage measured on the pads. This change in voltage is registered as a button press by the Fast Touch™ system.

As a function of this button press, the Fast Touch™ system can be configured to do the following:

Features

- USB HID - Map any button press to a key on a computer keyboard, mouse or joystick

- General Output - Active HIGH or Active LOW, Toggle or Momentary signal from general output pins

- FET Driven Output - Capable of driving loads for example bright LED Lighting

- Data Communication - TTL Serial UART, RS232, I2C, SPI, USB, etc. can communicate button presses with simple protocol

- Audio Feedback - Produce Audio feedback to hear a custom sound during button actuation

The Fast Touch™ system can also communicate the button press and release data to your electronics using one or many of the following methods

- SPI

- UART (TTL/RS232/RS485)

- I2C

- USB HID communication protocol

- Simple I/O

Has the UI / UX design of your capacitive touch control panel become overwhelming?

Let our UI / UX design team help! Just provide us with a simple understanding of your machine and what you are looking for!

Using Adobe XD, we can provide you with a web page link of your functioning user interface. You can open this link with a touchscreen laptop or tablet to get a real "touch" interactive experience. This link can be easily shared to all of the decision makers within your organization for quick approval.

Here is an example of a recent capacitive touch keypad and control system we made. This keypad has all of the control electronics and software required to control this air purification machine. It has a glass overlay and uniform selective LED lighting. There is also a dead front indicator telling the user when to replace the filter. Touch or click the power button, timer buttons, speed buttons, and the Dead Front "Change Filter" text, to see how they operate.